FAQ

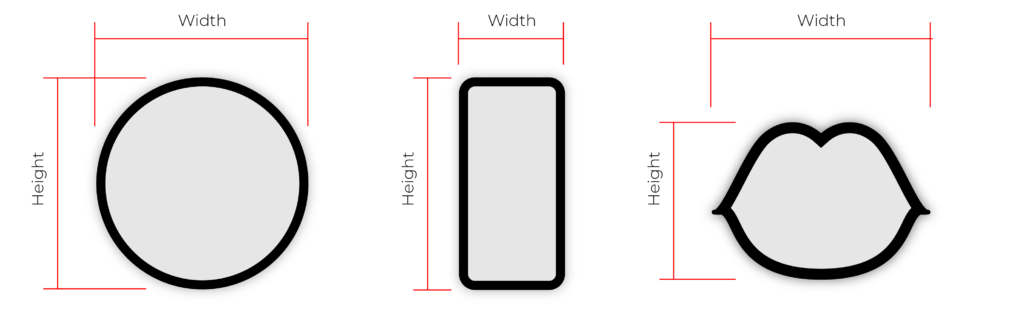

What dimensions to use

By entering the height and width of your stickers into our online calculator, you can see the expected dimensions of the finished project. The numbers entered into the calculator should not include bleeds.

How to prepare files for printing

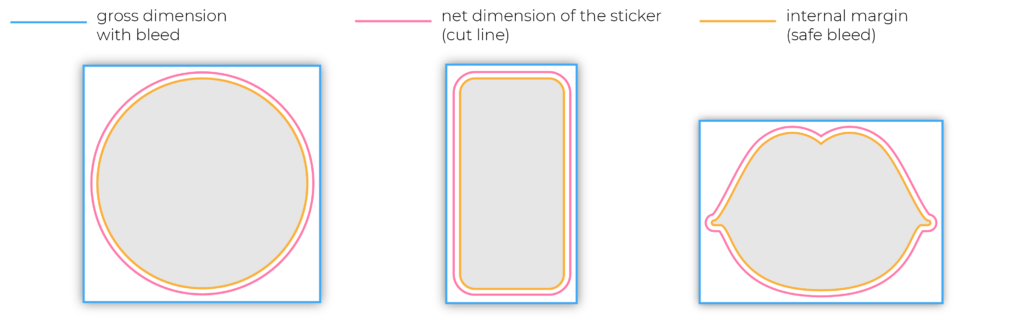

Size/Bleeds – files marked for printing should be prepared in the target size (1:1 scale) with 2mm bleeds. In other words, 2mm should be added to each side of the sticker. These bleeds are needed to compensate for possible imprecisions during cutting.

Internal margins – so-called safety margins should be about 2 mm

Resolution – graphics and photos should have a resolution of 300 dpi (minimum 220 dpi)

Crop marks (sticker shape) – these should be provided on a separate page or in a separate file. There is no need to provide crop marks for stickers in standard shapes (circles, ovals and rectangles), as long as the shape of the sticker is supposed to match the design. The corners of rectangular stickers are normally rounded (radius of 2-3 mm, depending on the size of the sticker).

Colours – the entire file should be prepared in the CMYK colour model. Anything prepared in RGB will be converted to CMYK. The conversion of RGB to CMYK generally results in colour changes due to differences in the way digital devices reproduce colours. Each device renders colours differently. Due to technological limitations, printers are not able to reproduce colours that are identical to those seen on most monitors.

White (mask) – this is used for the printing and under-printing of projects on transparent vinyl. The white colour mask must have a homogenous black colour without shadows, without tonal transitions, etc. (C=0 M=0 Y=0 K=100). A vector file type (PDF or EPS) with text converted into vectors/outlines is required to print white stickers.

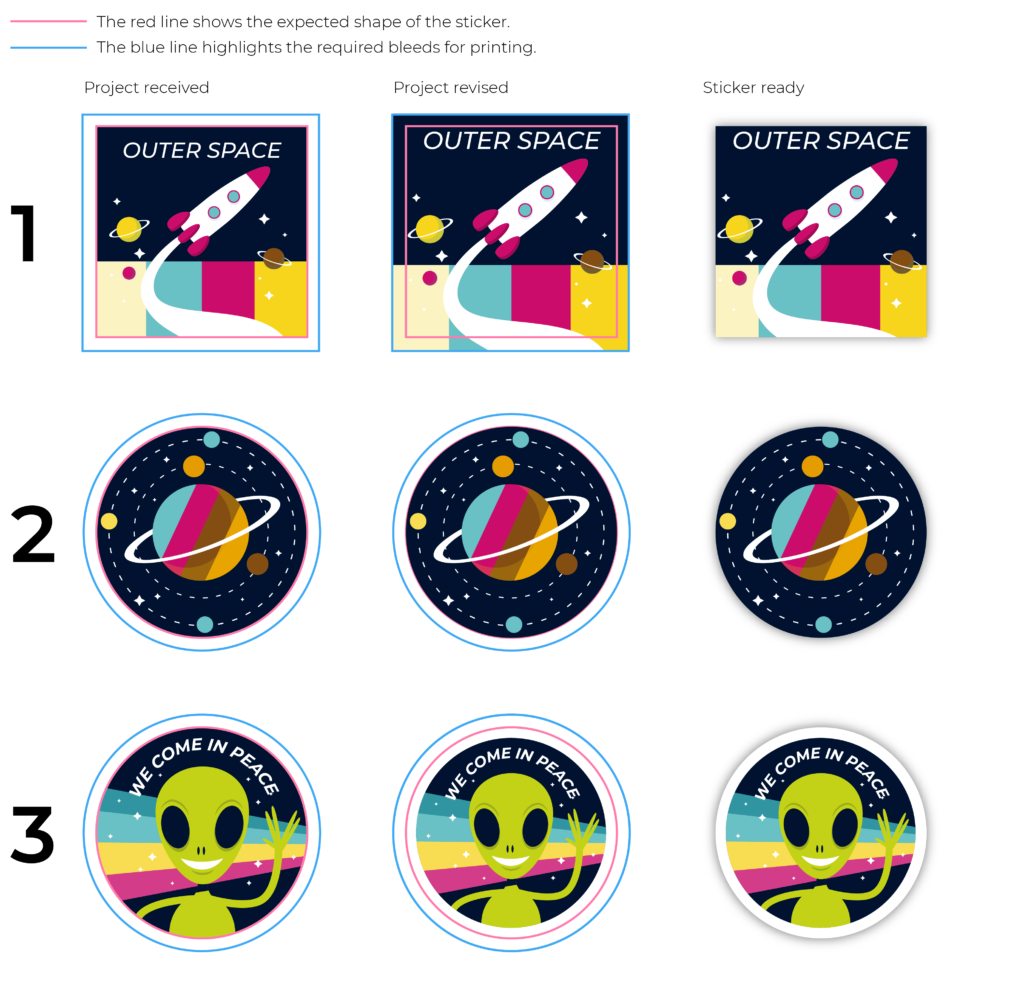

IMPORTANT! We operate under the assumption that our customers are sending us the best files they have and we strive to avoid printing delays due to file issues. Our team will therefore correct the most commonly seen errors such as a lack of bleeds and problems with the colour space.

To fix these problems, we can:

- extend the image to generate bleeds

- for stickers with a uniform background, we may be able to generate bleeds ourselves by determining the background colour through sampling

- as a last result, we will add a white border, which will decrease the size of the image in the process

- colours are converted into CMYK using the international standard “Coated Fogra 39 (ISO 12647-2:2004) The image below shows some examples of bleed fixes

The red line shows the expected shape of the sticker.

The blue line highlights the required bleeds for printing.

The image below shows the colour differences that result from converting RGB to CMYK.

How to prepare images for the printing of transparent stickers with a white underprint

A white colour mask is used for the printing and underprinting of stickers on transparent vinyl. The mask must be filled with the colour C=0 M=0 Y=20 K=0 or #FFFCD5. A vector file type (PDF or EPS) with text converted into vectors/outlines is required to print white stickers. The sample project in the image below has been saved as three separate files – image for printing, white colour mask and crop marks.

How do you produce stickers in any shape?

Our stickers are cut with the help of digital die-cut machines (cutting plotters). This allows us to cut out stickers in any shape ranging from simple shapes like rectangles, circles and ovals to more complicated shapes such as those shown in the images below. The use of cutting plotters is ideal for small and medium-sized print runs, and is cheaper than the use of flat or rotary cutting dies.

How will I receive my stickers?

Stickers can be delivered already individually cut out, as sticker sheets (multiple stickers on a single page similar in size to A4), or completely free of processing.

How do we print stickers?

We use ecosolvent plotters to print our stickers. We exclusively use genuine ink cartridges, print in high resolution, and only print on substrates produced by trusted suppliers. Paper stickers are printed with laser printers. These stickers are also printed in line with the highest standards and using the best substrates. Details concerning the specific printing supplies and materials we use can be found on individual product pages.

How long will it take?

The date given in our online calculator indicates when the stickers will be sent to the customer. In other words, this is the date when we will hand your order over to the courier, who usually manages to deliver it within 24 hours (99% of packages are delivered within the indicated time).

Shipping costs

Stickers are sent via UPS, who usually delivers them on the next business day.

Prices:

How do we cut out our stickers?

All stickers are cut out with cutting plotters. To guarantee high quality work, our machines come from two leading manufacturers. In addition, our machines are equipped with photo sensors to ensure accuracy during parallel cutting.

How long do the stickers last?

Our vinyl stickers are resistant to fading for 3 to 5 years. They are also water-resistant. Paper stickers will last for 3 to 6 months when in the sun. Because paper stickers are not water-resistant however, they are usually not placed outside. As a result, their colours last much longer.

Further questions? Please call us.